Flexible PCBs or Semiflex PCBs: Which Should You Choose for Your Next Product?

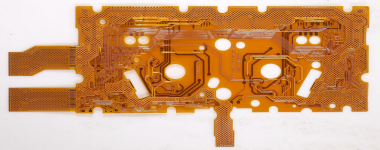

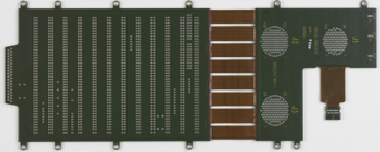

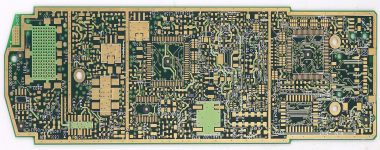

Modern electronics often need circuit boards that bend, fold, or fit into tight spaces without sacrificing reliability. That is where flexible PCBs and semiflex PCBs come in, but they solve design problems in different ways. A flexible PCB is built for repeated or static bending, making it ideal for tight routing and dynamic motion applications.