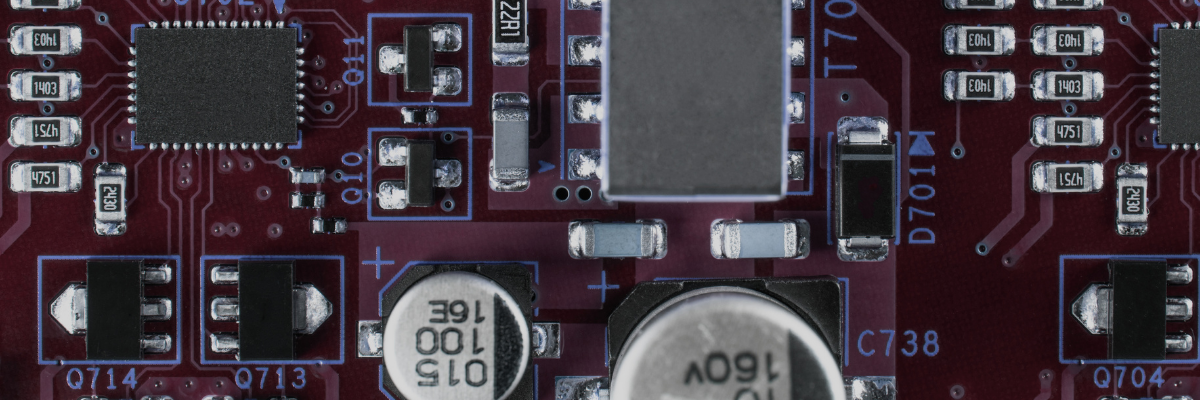

Be it any industry, printed circuit boards (PCBs) are making their presence felt in almost every application. The networking and communication applications are not an exception to this. These circuit boards help in making the communication, a hassle-free task. In these applications, printed circuit boards can be manufactured from different materials. What are these materials? Are you intrigued to know? The following post sheds some light on the different materials used to make PCBs for the networking and communication applications. Also, discussed in the post are various beneficial features and properties of these materials. Read on to know more.

What are the Different Materials Used in Networking and Communication PCBs?

The construction and designs of the printed circuit boards vary depending on their applications. Similarly, for networking and communication applications, different materials can be used for the PCBs. Here are some most commonly used materials:

370HR: 370HR are basically prepregs and laminates that are used on printed circuit boards. The printed circuit boards made using 370HR are RoHS compliant. The most common problem seen in PCBs is Conductive Anodic Filament (CAF), which is an electrochemical corrosion process. In this phenomenon, copper metal at anode dissolves and moves to the cathode. This creates electrical shorts, which is not good for any application, especially networking and communication. However, the 370HR PCBs are CAF resistant. Besides this, they feature high density interconnects, and an excellent thermal reliability.

Glass Epoxy FR4: The glass epoxy FR4 material has an excellent strength to weight ratio. In addition to this, this material is a versatile high-pressure thermoset laminate grade. This makes it suitable for use in networking and communication applications. In any condition, dry or humid, the glass epoxy FR4 PCBs are capable of retaining electrical insulating properties, as well as exceptional mechanical values. Furthermore, the material has an excellent mechanical strength, and is known for it’s near-zero water absorption.

High-speed Pyralux TK: The high-speed Pyralux TK material is mostly used in the PCBs for high-frequency applications. TK refers to Teflon-Kapton. This copper-clad bondply and laminate is generally double-sided. The bondply used in the material helps protect it from harsh environments, and provides a good electrical insulation. Fluoropolymers and polyimides are used for creating the primary composite. TK material is particularly designed for flexible digital circuit boards. Some more advantages of this material include low moisture absorption, better flexibility, and low dielectric constant.

Polyimide: This is yet another material, which is most commonly used in the networking and communication PCBs. The key benefit of this material is that it has an excellent thermal stability. This allows the material to withstand extreme heat in certain applications. The PCBs that use polyimide are known to offer a good base for surface mounting. Besides this, it is a cost-effective material option for PCBs.

Now that you know what are the different materials used for manufacturing PCBs for networking and communication applications, it would be easier for you to select the right material, depending on our requirements. Are you still confused about choosing the correct material? In such cases, it is advisable to consult the experts, who can guide you with the right material selection for your PCB. Rigiflex is one such experienced manufacturer of high-quality PCBs for a wide range of industries, including aerospace, medical, telecom, networking and communications, and more