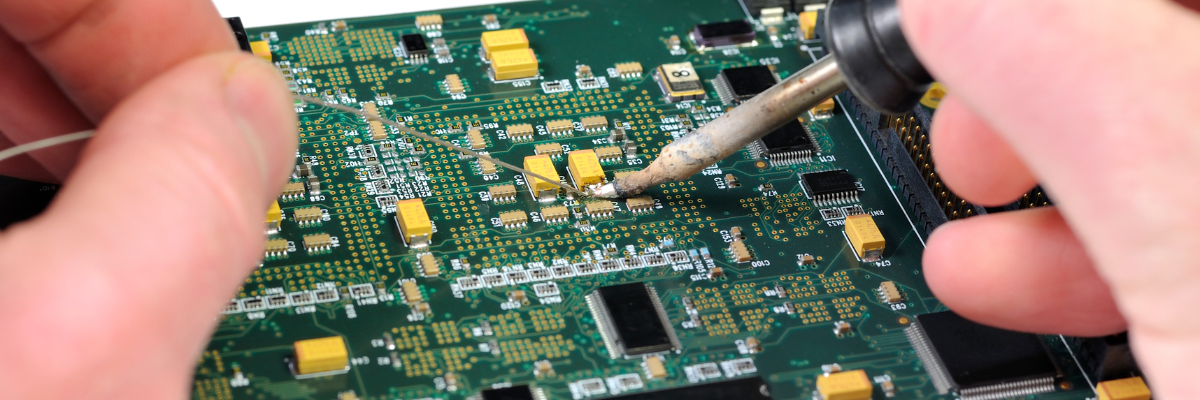

Fast turn turn Printed Circuit Boards (PCBs) production follows a series of steps and streamlined processes, which allow manufacturers to boost their time-to-market capabilities and maintain a competitive edge. The earlier post discussed the benefits and steps involved in fast turnaround rigid flex PCB manufacturing; however, this post will delve into other things you must be aware of when opting for fast turn PCB manufacturing services for your next project.

Factors that Affect the Cost of Fast Turn PCB Production:

When it comes to making PCBs within a short timeframe, various aspects can influence the production cost. It is imperative to understand these factors clearly to manage expenses effectively without compromising on the desired specifications and quality standards for your PCBs.

- Design: Design complexity is a key factor that affects the cost of fast turn PCB production. The more intricate the design, the more expensive it is to manufacture. Designs that require more layers, special materials, or complex routing patterns will naturally take more time and resources to produce, increasing the cost of production.

- Quantity: The quantity required is another important factor that directly affects the cost of fast turn PCB production. Generally, the more boards required, the lower the cost per unit will be. This is because larger orders can be manufactured more efficiently, resulting in lower production costs.

- Types of Materials: The cost of fast turn PCB production is influenced by the choice of materials as well. Advanced materials and technologies like flex PCBs or high-temperature materials are typically expensive, resulting in increased production costs. Nonetheless, these materials are essential for specific industries like aerospace and must be considered when calculating the overall cost.

- Surface Finish: Different surface finishes, such as HASL, ENIG, and OSP, have different costs associated with them.

- Speed: Lastly, the speed of the turnaround required can also impact the cost of fast turn PCB manufacturing. Faster turnarounds may require expedited shipping or special processing techniques, which can increase the overall cost of production.

Factors to Consider When Selecting Fast Turn PCB Production Services Providers:

PCB assemblers rely on specialized equipment and facilities, along with cutting-edge software and automation tools to meet the demands of fast turn PCB production. It is critical to partner with experienced fast turn PCB manufacturing services to meet your quick turn PCB needs. Selecting the right service provider can be a challenging task, given the several options available in the market. It is highly recommended to make a well-informed decision, as the quality of PCBs can impact the functionality and reliability of electronic equipment significantly. Therefore, it is crucial to consider several factors as listed below before choosing a fast turn PCB production services provider.

- When choosing a service provider for your fast turn PCB design and manufacturing needs, it is important to check out the level of technical expertise and experience they possess. The company you select must have a team of experienced engineers who are capable of managing the intricacies associated with your project.

- Check out the production capacity of the services provider. Make sure they can handle both low and high-volume production runs. Additionally, verify that they have a reliable supply chain of high-quality PCB components to make a smooth material procurement, which in turn enhances the speed of final product delivery.

- It’s also important to consider the cost of services provided by the company and their pricing structure. Compare the costs of various service providers and ensure that their pricing is transparent.

Other factors to consider include certifications, quality control processes, technical support, and customer service.

With the discussion in the last and this post, you might have gained a clear understanding of fast turn PCB production. Now, you should know about a prominent provider of quick turn PCB services in the market to associate with for your next project. This post ends by letting you know about a leading service provider Rigiflex, who offer a range of PCB manufacturing services, including flex and rigid-flex circuit boards, with guaranteed delivery in 1-5 days. Rigiflex offers customized end-to-end PCB solutions with extremely flexible manufacturing capabilities. They have high-quality PCB manufacturing capabilities and certified standards of excellence, giving them an edge over their competitors in the marketplace. Get in touch with the team at Rigiflex and see how can take help you in your next fast turn rigid flex PCB production.

By carefully considering each of these factors, you can invest in passive components that not only contribute to the functioning of the PCB but also to its overall performance and reliability. The next post in this series focuses on the active board components and their role, and offers tips for their selection.