FR-4 is a glass epoxy laminate sheet that is most commonly used in PCBs (Printed Circuit Boards). It is used in all kinds of flexible printed circuit boards, and other semi-rigid variants. It displays excellent properties of high strength and flame resistance among others. The ease of integration in applications and allowance of component mounting has made it a preferred material in most PCBs.

Production Process of FR-4

Fiberglass sheets are impregnated with epoxy resin. These sheets are used to construct FR-4. Eight of these reinforced sheets are covered with a copper foil layer. This entire construction is then placed in a press, which bonds it into a single FR-4 sheet.

Materials Used to Fabricate FR-4

The glass present in the FR-4 sheet makes it extremely strong. The epoxy resin used is generally flame retardant unless otherwise specified. Bromine is used to lend the epoxy its flame retardant properties. This makes the entire PCB flame retardant. This is of immense importance in most applications that are associated with high temperatures.

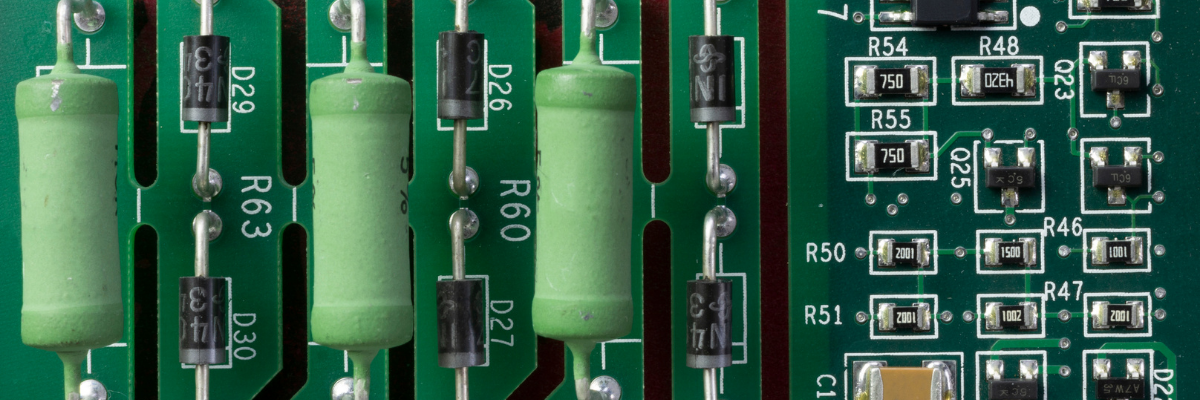

The copper used helps designers and fabricators etch patterns onto the PCB. These etched patterns form the basic circuitry that connects the various components. It also connects the interconnectors to the basic circuitry. Interconnectors are used to connect the various layers of a PCB.

Dicyandiamide also known as ‘dicy’ is a material most commonly used to harden epoxies. It has a maximum temperature allowance of 300 ˚C. If an epoxy is cured using a phenolic based substance, it is known as ‘non-dicy’. It has a maximum temperature allowance of 350 ˚C.

FR-4 is used in single as well as multi-layer PCBs where the components are surface mounted. FR-4 offers ease of use from the fabrication point of view. Hence, it provides immense flexibility to the designer, allowing him to utilize the intrinsic properties of the material to the advantage of the application and process.