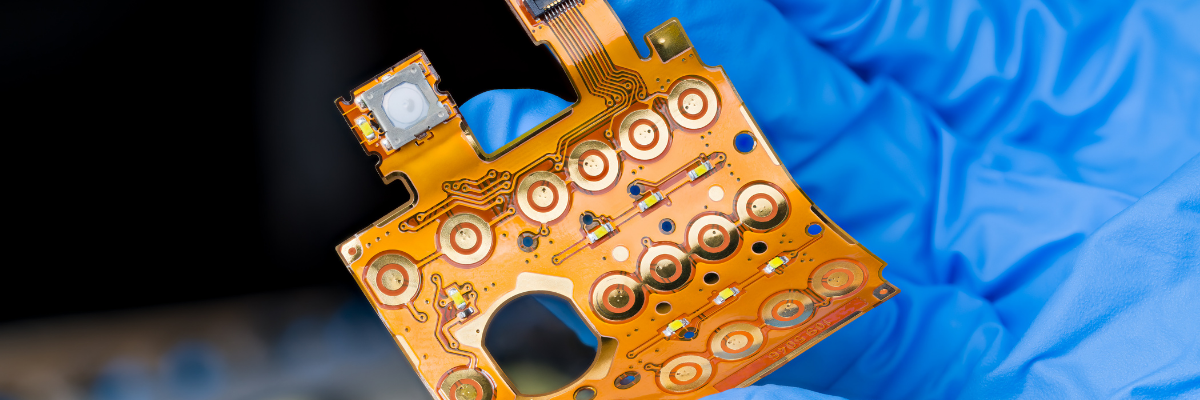

In the previous post, we covered the common solder-related problems that could occur during PCB assembly. As a consumer, you should be aware of these problems. This will be especially helpful when working with complex designs like 8 layer rigid polyimide PCBs. With this information on hand, you can check if the manufacturer has managed to assemble the PCB according to your requirements.

Problems You Should be Aware of When Designing Flexible PCBs

Improve the functionality of your PCB by ensuring that the following problems don’t occur:

1. Stress Points

Flexible circuit boards need to be flexible on demand or they can be installed in a folded manner. When the board bends, some parts of the circuitry will be more stressed than others will be. For instance, traces featuring sharp edges will experience physical stress when the board is folded. To avoid this stress, there should be no sharp corners. The circuitry should exhibit smooth corners and an overall rounded radius.

2. Stacked Traces

Stacked traces are those traces that are etched on the exact spot on the opposite sides of the dielectric. Due to their position, they experience stress, causing them to fracture. Traces etched on the top and bottom sides of the copper layers should be ‘staggered’, meaning no two traces should be aligned with one other.

In case you have an old PCB that is not performing up to your requirements, you can check for some of the above-mentioned factors that are often overlooked during PCB assembly. By doing this, you wouldn’t have to purchase new PCBs; you could get your PCB up to speed with some rework. This will help you in reducing your cost, increasing product efficiency, and reducing down time.

Five Common Problems Associated with Flexible PCB Assembly – Part I