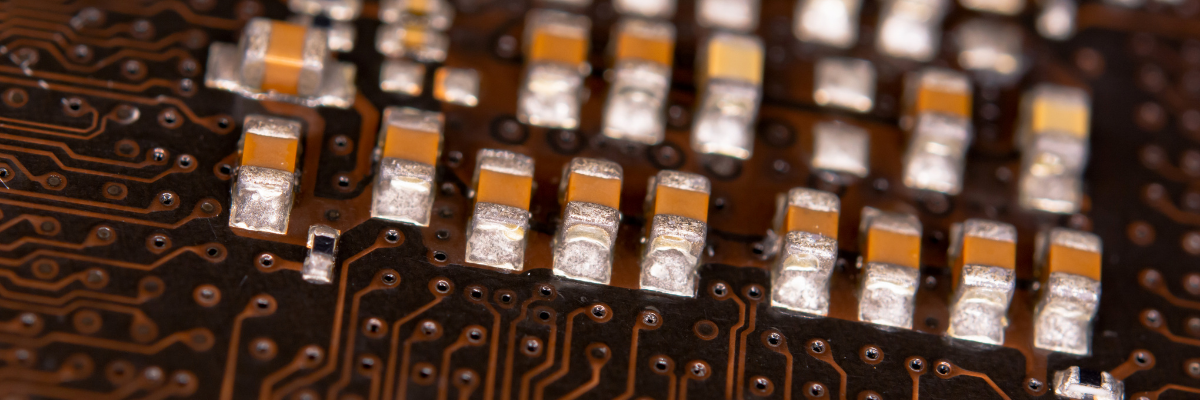

The PCB lamination process begins with the selection of suitable materials. Choosing the right laminate is crucial as it determines stability, lower loss, and optimum performance of the final assembly. Several laminate options are available to support the assembly of printed circuit boards. This blog familiarizes you with the four commonly used PCB laminate materials.

Types of PCB Laminates

The aforementioned are four recommended laminate types used in a PCB Assembly:

FR4 – This is the most commonly used laminate for surface mount assembly. It possesses good strength-to-weight ratio, and maintains excellent mechanical, electrical, and physical properties at elevated temperatures. The material is flame resistant as well, adding to its reliability.

High Tg Epoxy – This laminate is perfect for multilayer PCBs. The material exhibits superior thermal performance and exceptional chemical resistance. Offers excellent electrical insulation in applications with extreme humidity and temperatures. Tg Eepoxy is highly versatile, economical, and is flame retardant.

BT Epoxy – BT epoxy is widely chosen for its outstanding thermal, mechanical, and electrical properties. This laminate is suitable for lead-free PCB assembly. It is primarily used for multilayer board applications. It features excellent electro migration, insulation resistance, and high thermal resistance. It also maintains bond strength at high temperature.

Polyimide – This material possess superior circuit trace adhesion strength, and extreme environmental stability. Polyimide is ideally used to produce high density, flexible, rigid-flex circuit board, and multilayer PCBs. It exhibits excellent thermal, chemical, and mechanical properties, which makes the material ideal for advanced applications in military, aerospace, automotive, and consumer electronics markets.

Factors to Consider When Choosing PCB Laminates

No that you know the commonly used PCB laminates. Amongst the aforementioned types, which one to choose to assemble your PCBs? There are several factors to consider. A few of them include:

- Dielectric constant

- Loss factor

- Thermal conductivity

- Transition temperature

- Coefficient of thermal expansion (CTE)

- Electrical performance

- Ability to operate in varying thermal environments

Make the right choice as per the application and properties of the laminate. This is very important as the type and quality of laminate determines the service life and operational performance of printed circuit boards.