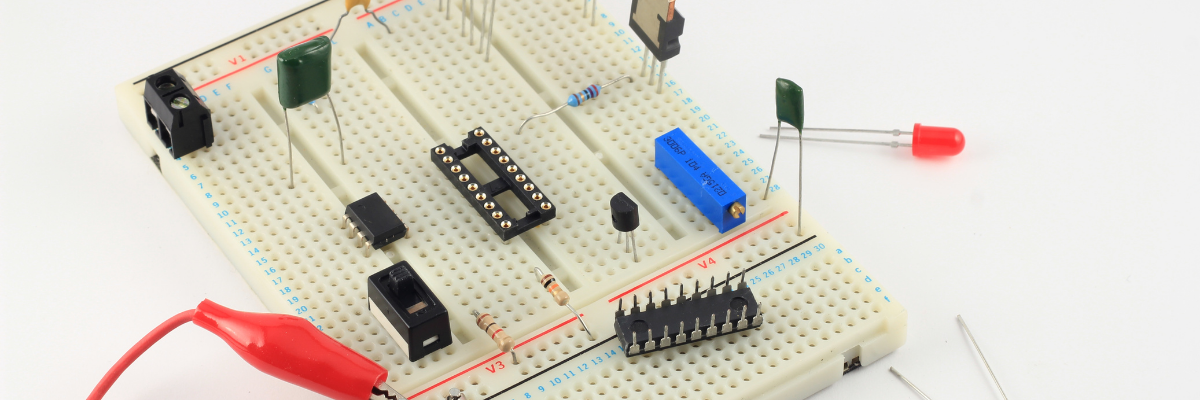

Electronic and electromechanical systems and equipment are used in many residential, commercial, and industrial facilities. Advents in electronics has revolutionized industrial processes at large. These systems’ performance and shelf life depend entirely on embedded circuit board assemblies and more so, their type, properties, and so on. Printed circuit boards (PCBs) and to some extent breadboards are popular among all substrates. They bring life into electronic devices. Breadboards are ideal for prototyping and experimentation, while PCBs offer a reliable solution for your electronics projects, and hence find mission-critical industrial applications. Is that all? Obviously not. Would you like to know more about PCBs and breadboards? How do you decide when to use a breadboard and PCB in your electronics projects? This post highlights some pointers which will help you understand this in detail. So, stay tuned.

5 Key Considerations for Transitioning from Breadboard Prototypes to PCBs in Your Electronics Projects

Several factors compare PCB vs. breadboard, including design aspects, complexity, component placement, and more. Although they are completely different terms, knowing when to use a breadboard and PCB in electronics projects is essential. Here are some factors that help you understand this in a better way.

- Complexity of Project: This is one of the important factors in determining whether to use breadboards of PCBs. Projects with simple design structures and minimal components can rely on a breadboard as they are easy to assemble and modify. PCB is the best option in case of complex designs, multiple functionalities of products and systems, and several connections and components. PCBs are known for handling intricate circuitry. On the other hand, breadboards can be used simply testing the circuitry and connections, which helps prevent any damage to the actual PCBs being made for a given application.

- Space Constraints: Given the ever shrinking size of electronic devices, PCBs also have shrunk and must be fitted in compact spaces. Space constraints impose limits on physical dimensions and available space within the device. Regardless of the number of components and layers, PCBs can be customized in terms of dimensions and shapes to fit in small spaces. Hence, it is important to consider the space availability in your device or machine. This reduces the overall footprint of a circuit board than a breadboard. PCB is the best choice when space is a major concern.

- Reliability and Durability: Breadboards have fewer connections and current carrying capacity compared to PCBs. Thus, they are great for testing and experimenting. Oppositely, several components can be placed and mounted neatly on PCBs. Hence, in the case of complex circuitry, transitioning from breadboards to PCBs is crucial if your electronics project requires durability and reliability, such as any industrial application or consumer electronics. Aside from durability and reliability, PCBs are known for offering robustness and stability, improving the performance and efficiency of the circuit.

- Production and Scaling: If the project extends beyond a single prototype and requires production in larger quantities, considering PCBs is a logical step. The manufacturing of circuit boards allows for consistent production with utmost accuracy, especially on CNC machines. Once the design is finalized, replicating it on multiple PCBs becomes cost-effective and efficient. This is mainly helpful for commercial or mass-production applications.

- Noise and Signal Integrity: Breadboards have limited current carrying ability and hence may cause signal degradation and noise in sensitive components or high frequency applications. On the other hand, the circuit boards can be designed keeping signal integrity in mind. You can include in their design the required ground planes, controlled impedance, and shielding options, ensuring cleaner and more reliable signal paths. This makes them ideal for high-frequency or precision applications.

Both breadboards and PCBs are different in their own way. Their advantages and limitations make them ideal for different applications. Considering these pointers, you can easily choose when to use breadboards and PCBs. If you have any doubts, it is always best to consult a reliable and experienced PCB manufacturer and assembly service provider in the USA. Rigiflex Technology stands tall among its other competitors. The company has several years of market presence and expertise in making custom PCBs for mission-critical applications. In case of any further information, you can contact their team experts today.