Copper is an integral part of Printed Circuit Boards (PCBs). However, PCB manufacturing is a tedious process that requires balanced consideration of technical specifications. One of those considerations is copper balance in the PCB. Copper is used in PCBs due to its excellent electric conductivity. However, the imbalanced application of copper in PCB fabrication can lead to issues like bows and twists. Since PCBs are important components of electronic industrial circuits, a slight error in fabrication may lead to massive losses. That is why the copper balance in PCB fabrication is essential. To prevent certain errors, copper balance in PCB fabrication must be achieved by the manufacturer. This post discusses the importance of balancing copper in PCB fabrication and ways to achieve the same.

Significance of Copper Balance in the PCB Fabrication

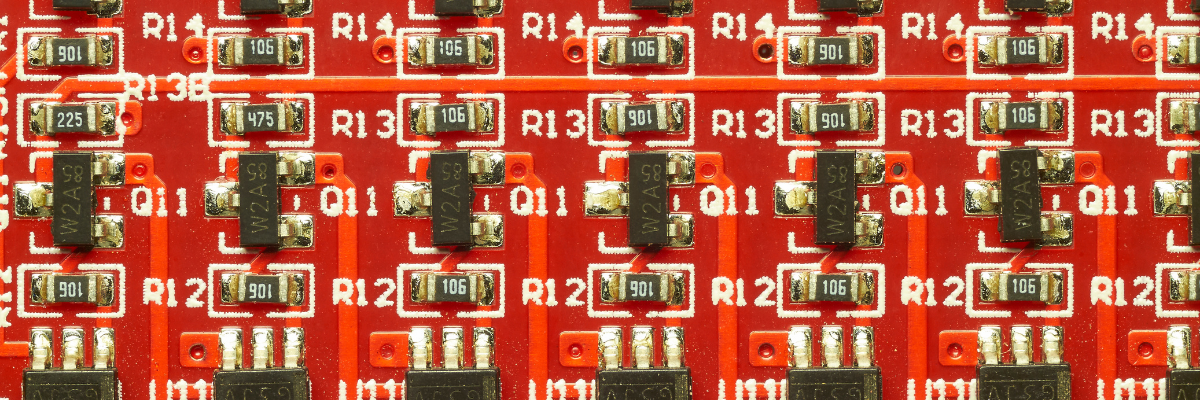

Copper is an electric conductor, which is used in various forms in the PCB. The elements like traces, core, layers, and final coating consist of copper as the main component. If copper coverage is inconsistent between the layer stack-up, it can lead to issues like bows and twists, warpage, etc.

Let us discuss the problems that need to be avoided by the proper copper balance in PCB fabrication.

- Bows: Inconsistent copper coverage causes cylindrical or spherical curvature on the PCB layer, this is known as the bow. The bow causes tension or compression on the surface of PCB according to the direction of the bend. This can lead to the inconsistent circulation of electric current across the board.

- Twists: If one of the corners of the PCB is not parallel to the others, the surface lift from one end of the diagonal and surface depth on the other ends create a twisting effect. The twist causes stress in the PCB layers.

- Warpage: Inconsistent layering of copper on the PCB leads to warpage. The warpage is also known as the potato chip effect. This may cause saturation of electric current and ununiformed distribution of current across the board. It can also interrupt the function of traces and connection leads of mounted components.

To prevent such errors in the PCB fabrication proper copper balance in PCB must be achieved.

Let us discuss different ways to achieve copper balance via consistent layer stacking.

Ways to Achieve Consistent Copper Balance in PCB Fabrication

Copper balance is all about proper layer stack-up and layer configuration in the PCB fabrication. Adopting the following 4 tactics in PCB design can help in achieving copper balance.

- Consistent Layer Stack-up: Since the layer stack-up is designed in an outward direction, from the center to the outer edge. Applying consistent layer thickness while stacking up the layers helps in copper balancing. Ensure that the potato chips effect does not occur while layering the copper layers. Also to prevent twisting, it is important to ensure that one side of the layer mirrors with another end of the layer.

- Symmetrical Planes: The power planes should be layered symmetrically without affecting the impedance and integrity of signal flow. Also, the copper weight on different power planes should be the same as it contributes to the copper balance.

- Copper Add-on: Often the cross-hatched areas of PCBs lack copper density. Lack of copper density may lead to bows and twists. To cover this lack, a copper add-on can be done. Layering additional copper in the cross-hatches areas of PCBs can help in overcoming the lack of copper density.

- Prepreg and Core Symmetry: Ensure the uniformity and proportions of copper usage on the prepreg and core. Symmetry in the surfaces of the prepreg layer and core should be maintained to balance copper.

Since copper balance in PCB fabrication is such an important factor, it is better done by experts. That is why you should source PCB fabrication services from industry experts like Rigiflex Technology, Inc. They manufacture high-quality PCBs that are designed and fabricated in compliance with ISO-9001, AS 9100, UL, IPC-6012/6013, MIL-PRF-31032, etc. Owing to the compliance with these industrial standards copper balance in PCB fabrication and quality of their PCBs is assured.