There are a number of steps involved in the manufacturing of a printed circuit board (PCB). Out these several steps, selection of material for the PCB goes a long way in deciding its performance, as well as its scope application. The base material of a PCB, is therefore very important. Different types of base materials are used based on the application requirements of the PCBs. Based on the flammability characteristics of a circuit board material, they can be of different types, which include CEM 1 (single-sided fiberglass board), CEM 3 (double-sided half-glass board), 94V0 (flame retardant cardboard), 94HB (non- fireproof cardboard), 22F (single-sided fiberglass board), and FR4 (double-sided fiberglass board). In this post, we will discuss in detail about the FR-4 material used in the printed circuit board. Why is this material used? What are its properties? Please read the following post to know.

What is an FR-4 Material?

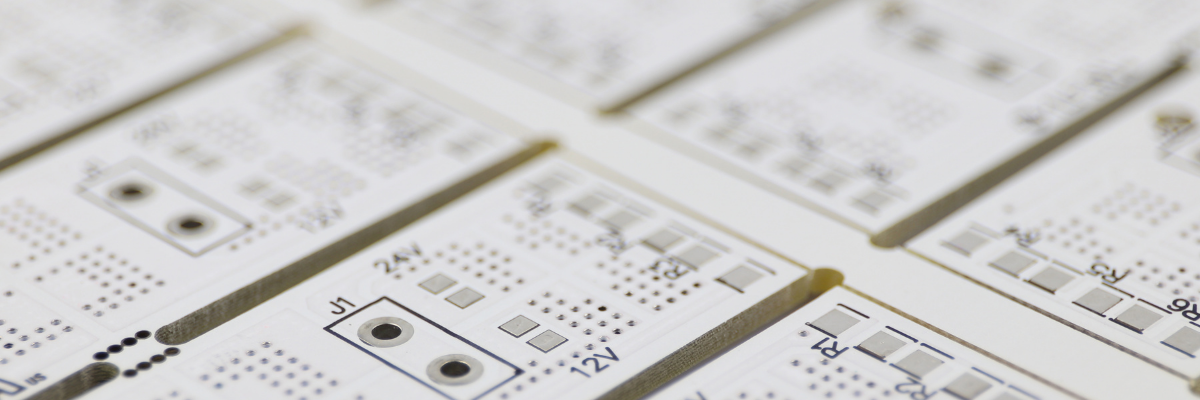

FR for in FR-4 material stands for fire retardant, which means that the material is self-extinguishing. It is basically a glass fiber epoxy laminate, which is most widely used in manufacturing printed circuit boards. This material conforms to the UL94V-0 standards, and is an international grade material, which has been accepted widely for fiberglass reinforced epoxy laminates. The material consists of bromine, which is the main factor that makes it a fire retardant. The FR-4 material is most commonly used in prototypes. In the prototyping stage, the circuit boards are pushed to their extremes for testing purpose. Thus, the FR-4 material is highly suited for prototype circuit boards.

When each side of this material is added with a copper layer, it is referred to as a Copper Clad Laminate (CCL). Now, this is a non-conductive core material, and can be used for normal printed circuit boards. However, those PCBs, which use FR-4 material are referred to as FR-4 printed circuit boards.

What Properties of FR-4 Material Make it so Special?

Here are some properties of the FR-4 material, which make it one of the most preferred materials for manufacturing printed circuit boards:

- Flexural Strength â 100,000 lbf/in2 (lengthwise); 75,000 lbf/in2 (crosswise)

- Glass Transition Temperature â 135 °C

- Dissipation Factor @1MHz â 0.014

- Glass Transition Temperature (Tg) â 150Tg or 170Tg

- Dielectric Constant @1 GHz – 4.25-4.55

- Compatibility â Standard and Lead-free Assembly

What are the Various Types of PCBs Designed Using FR-4?

When you select FR-4 as a material for your printed circuit board, you can design various types of PCBs, such as:

- Single Sided (S/S), or Single layer

- Double Sided (D/S), or double layer, 2Layers, 2L

- Four Layers (4L), Six Layers (6L), Eight Layers (8L), Ten Layers (10L)

- Board with more than 10 layers (10L)

These all were the features that explain the reasons behind the increasing popularity of this material for manufacturing printed circuit boards. The FR-4 PCBs are among the widely used printed circuit boards in a wide range of applications. There are a lot of manufacturers who provide these PCBs. There are very few manufacturers of FR-4 PCBs, such as Rigiflex, who have the required skill set and experienced staff, who can take care of your requirements efficiently.