Wondering if smart textiles or e-textiles are safe and comfortable to wear? Yes, absolutely. Smart textiles have conductive fibers and sensors, and yet they are designed to withstand the rigors of daily use and washing. Smart textiles are widely used by athletes, and so one can imagine their sweat-absorbing capacity. These advanced fabrics are truly transforming industries such as healthcare, sports, military, and fashion. Flexible PCBs are used to make smart textiles because they are lightweight and bendable. Depending on the requirement, rigid-flex PCBs may be used. Rigid-flex PCBs offer both flexibility and strength, providing support where it’s needed. This post looks at how flex and rigid-flex PCBs are used in making game-changing smart textiles, their future prospects, and more.

Understanding Flexible and Rigid-Flex PCBs

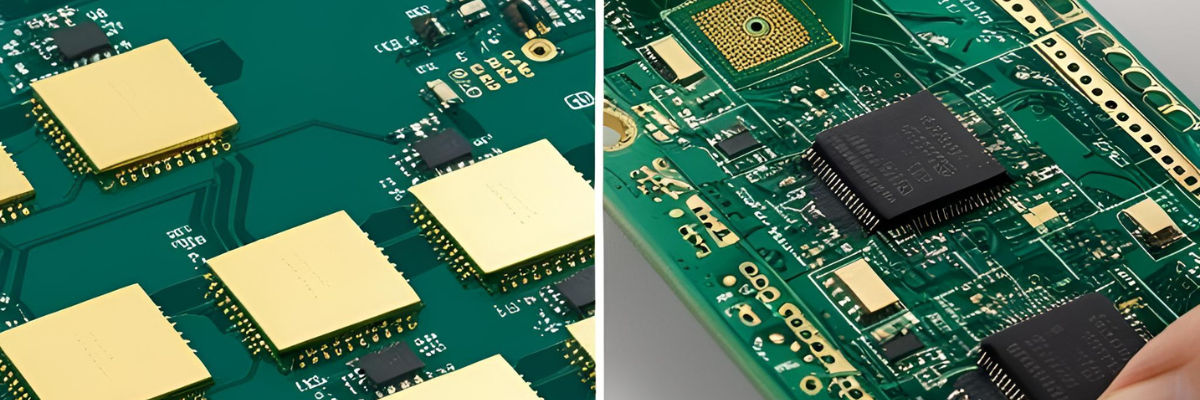

Flexible Printed Circuit Boards (FPCBs) are ultra-thin, lightweight circuit boards that can bend, twist, and fold without breaking. These are made using polyimide (PI) or other flexible substrates that allow them to conform to unique shapes and movements. Rigid-flex PCBs are hybrid circuit boards that combine rigid and flexible layers, providing the structural stability of traditional PCBs along with the adaptability of flex circuits.

Role of Flexible and Rigid-Flex PCBs in Smart Textiles

The integration of flexible or rigid-flex PCBs in smart textiles ensures that electronic components seamlessly blend with fabrics while maintaining functionality, durability, and comfort. With their lightweight design, adaptability, and high durability, these PCBs are enabling innovations in wearable health tech, sports performance tracking, and fashion technology.

Benefits of Using Flexible and Rigid-Flex PCBs in Smart Textiles

Here are some benefits of using flexible and rigid-flex PCBs in smart textiles:

-

- Lightweight and thin design for smooth integration: Flexible PCBs (FPCBs) have an ultra-thin and lightweight structure, perfect for integration into fabrics. FPCBs conform to the natural shape and movement of clothing. They ensure wearables remain comfortable and breathable. Also, they reduce weight, making smart textiles feel like regular clothing.

- High durability and flexibility for wearable applications: Smart textiles are often subjected to bending, stretching, and environmental stress, requiring electronic components that can withstand repetitive movement. Flexible and, to a certain extent, even rigid-flex PCBs are bend-resistant, stretch-tolerant, and highly durable, ensuring that the embedded electronics continue to function even after extended use, sweat exposure, and washes.

- Enhanced connectivity & signal reliability: Smart textiles require constant and reliable data transmission for accurate monitoring and analysis. Accurately designed flexible and rigid-flex PCB assemblies reduce signal interference and improve overall connectivity by eliminating unnecessary junctions.

- Improved power efficiency for extended battery life: Wearable smart textiles require efficient power management to ensure long battery life. Rigid-flex and flexible PCBs are designed with optimized power consumption in mind that allow wearables to operate longer without frequent recharging.

- Customization for various applications: Flexible and rigid-flex PCBs can be customized for specific applications. Whether it’s for medical wearables, smart sports gear, military uniforms, or interactive fashion, these PCBs can be tailored to meet specific industry as well as individual needs.

- Space saving & miniaturization capabilities: With the rise of miniaturized electronics, space-saving design is a critical factor in smart textiles. Even small-sized flexible and rigid-flex PCBs allow for compact and efficient circuit layouts, enabling designers to embed sensors and electronic components without adding bulk weight.

Applications of Flexible and Rigid-Flex PCBs in Smart Textiles

Here’s how flexible and rigid-flex PCBs are shaping the future of smart textiles.

- Health monitoring wearables: Smart textiles embedded with flexible PCBs are transforming healthcare wearables, providing real-time monitoring of vital parameters and medical conditions. By integrating biosensors, temperature monitors, and ECG circuits into clothing, medical professionals and patients can access continuous health data without intrusive devices.

- Sports and fitness wearables: Athletes and fitness enthusiasts are increasingly relying on wearable smart textiles to track performance, optimize training, and prevent injuries. Flexible PCBs allow electronic sensors to be embedded in sportswear, ensuring real-time physiological data collection without restricting movement.

- Smart textiles in military: In military and defense, and industrial sectors, smart textiles equipped with rigid-flex and flexible PCBs provide enhanced safety, communication, and performance tracking. These next-gen uniforms monitor soldiers’ health, detect environmental hazards, and facilitate real-time data communication.

- Smart safety & emergency response gears: Smart textiles are being developed to improve workplace safety, emergency response, and disaster management. These fabrics allow for real-time monitoring of environmental and physiological parameters, and hazard detection.

The integration of flexible or rigid-flex PCBs into smart textiles is revolutionizing wearable technology across multiple industries. Whether it’s healthcare, fitness, military, fashion, or industrial applications, these innovative circuit solutions enable seamless, lightweight, safe, and durable electronic integration.

Are you looking to develop next-gen smart wearables? Explore Rigiflex’s Flexible PCB Solutions and Rigid-Flex PCB Solutions to bring your vision to life! As a leader in high-performance PCB solutions, Rigiflex is committed to delivering cutting-edge flexible and rigid-flex PCB assemblies to support the future of smart textiles.