Double sided more core PCB’s (MCPCBs) are prominent features of high technology applications. These PCBs are gaining popularity over single layer PCBs due to various advantages that they offer. It is quite obvious for you to ask how they differ from single layer or double layer PCBs. What advantages do they offer? What are the applications of these PCBs? Read this post to get all answers.

A Brief Introduction to Double Sided More Core PCB

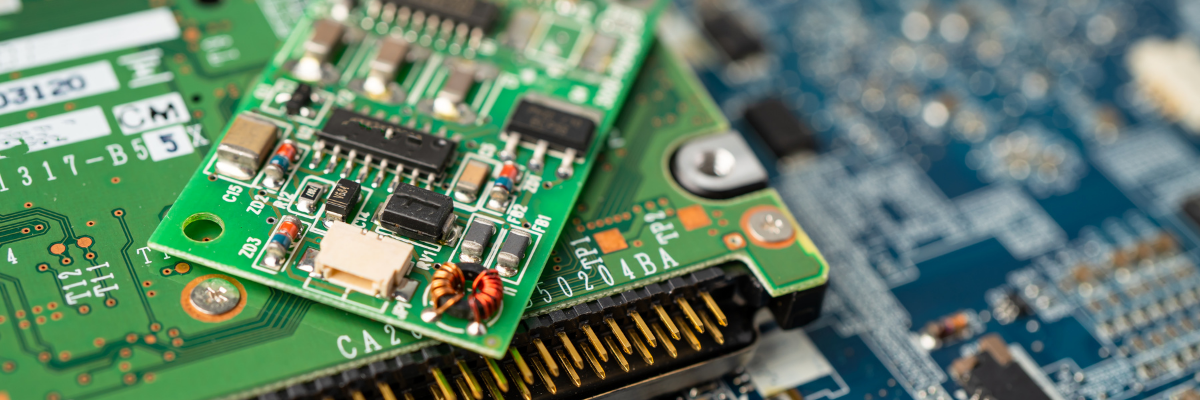

These PCBs have two layers of copper conductors like double layer metal core PCBs, but the metal core lies in the middle of these conductors. The conductors are connected to each other through vias. The SMD can be populated from top and bottom.

The double sided MPCB requires an addition pressing step for laminating the conductive material to the metal core. Many PCB vendors provide board materials that are already laminated.

In comparison to single layer or double layer PCB, these PCBs require experience and technology to laminate the two conductor layers with the metal core.

Benefits of Double Sided More Core PCBs

The following benefits of these double sided MPCBs make them popular with electronic manufacturers:

- Compact Sizes: Today, electronic manufacturers are competing against each other to market lightweight and compact sized circuits. They are relying on double sided PCBs to achieve their purpose. Reason? Components over these PCBs are surface mounted, which allow systematic and precise placement of components. This accuracy in placement helps more component placement and effective use of the PCB. Also, there is reduced need of interconnection wiring. This helps build compact sized PCBs.

- Improves Circuit Density: Two layers of conductors are always better than one layer. Why? These layers allow PCB designers to include more tracks and connect components. Also, they can increase IC connections through high pin counts. This is also one reason for compact sized PCBs.

- Easy Incorporation of Controlled Impedance Features: By now you might have understood the type of flexibility that these PCBs offer to a PCB designer. In addition to this, the presence of double or multiple conductor allows a PCB designer to control the impedance by varying spacing and dimensions of a particular laminate or trace.

- Controlled EMI Shielding: Today, PCB designers are able to offer high performance double sided PCBs because they can create EMI shielding by careful placement of ground and power layers.

Applications of Double Sided More Core PCBs

No wonder, due to the above mentioned benefits, these PCBs are regularly used in applications such as:

- Automotive dashboards

- Printers

- Traffic Systems

- Vending Machines

- LED Lighting

- Hard Drives and many other applications

Do you want to know how these double sided more core PCBs can benefit your applications? You should approach an industry expert for a more detail. He will understand your concern and provide you the right solution. If you wish to build these PCBs for your application, you need to approach a reliable company like Rigiflex. The company has delivered performance oriented double sided more core PCBs to its clients in diverse industries.