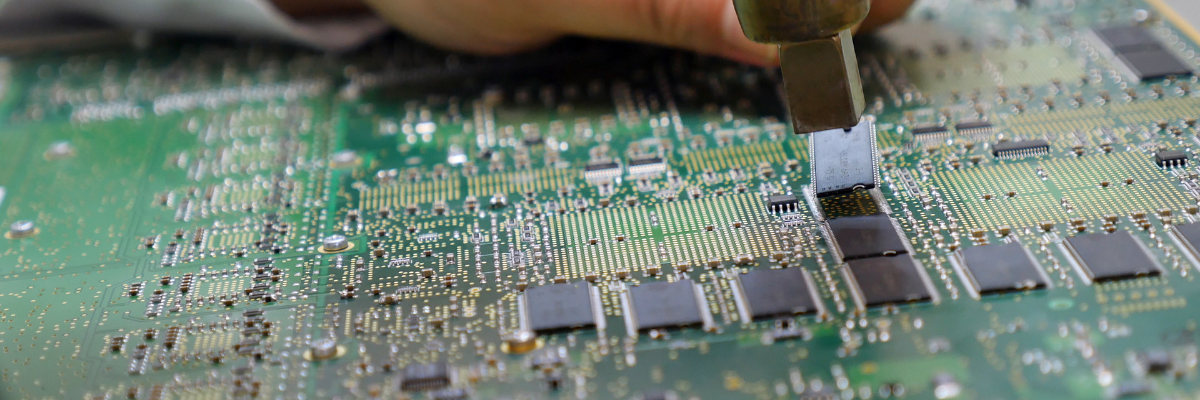

The Institute of Printed Circuit Boards (IPC), has proposed certain recommendations and guidelines to design, manufacture, and inspect Printed Circuit Boards (PCBs). IPC certification is only awarded to PCBs, which comply with IPC safety standards. PCBs with the certification offer a guarantee of outstanding quality, unfailing performance under stressful environments, and long lasting service life.

In this blog, we will discuss IPC’s standards on material selection for PCB assembly.

PCB Material Selection – An Overview

There are several material options available for producing PCBs. These vary from standard to highly sophisticated materials. However, selecting the right material according to specific application requirements is crucial. The following points must be considered when selecting PCB materials.

-

- Laminates – The choice of laminate greatly determines the structural strength of the final assembly. IPC recommends the following when choosing laminates:

- Choose a type that is easily accessible in a wide range of specifications.

- Avoid using special laminates, unless the PCB design demands the same. These can be costly, and will have longer lead times.

- Compare laminates against several parameters. These include easy machinability, trouble free processing, and processing costs. Choose the most appropriate material according to your needs and budget.

- Select a laminate that can withstand the rigorous manufacturing process and operational stress.

- Adhesives – There are varieties of adhesives available to bond layers of copper foils, and laminates. IPC recommends selecting the appropriate adhesive after considering its hardness, Coefficient of Thermal Expansion (CTE), and dielectric strength, among many others. Moreover, the type of adhesives chosen must be compatible with manufacturing processes, operational stress, and application conditions.

- Laminates – The choice of laminate greatly determines the structural strength of the final assembly. IPC recommends the following when choosing laminates:

IPC recommends to make an adhesive selection from the following options.

-

-

- Epoxies – Exhibit outstanding chemical resistance, thermal conductivity, and hardness.

- Silicon Elastomers – Possess good thermal vacuum stability, tensile strength, and hardness.

- Acrylic – Exhibit good electrical and adhesive properties.

- Polyurethanes – Possess high elasticity, toughness, moisture and chemical resistance.

-

Along with these, IPC recommends using specialized acrylic based adhesives, polyesters, polyamides, rubbers resins, and vinyl for the bonding applications.

-

- Metallic Coatings – Choosing the right metallic coating is of paramount importance as they provide benefits of outstanding corrosion resistance, long term solderability, and abrasion resistance. IPC recommends choosing among the following options to add protection to PCBs.

- Electroless Copper Plating

- Semiconductive Coating

- Electrolytic Copper Plating

- Gold Plating

- Nickel Plating

- Tin/Lead Plating

- Solder Coating

- Electroless Nickel and Immersion Coating

- Palladium Nickel Alloy

- Metallic Coatings – Choosing the right metallic coating is of paramount importance as they provide benefits of outstanding corrosion resistance, long term solderability, and abrasion resistance. IPC recommends choosing among the following options to add protection to PCBs.

IPC – Association Connecting Electronics Industries

Following the recommendations contained herein greatly contributes in producing successful PCBs.

Log on to http://www.ipc.org/, if you would like to know more about the generic standards and guidelines proposed by IPC. Understanding and implementing IPC requirements in the PCB design. This helps you produce boards that meet superb performance standards, outstanding functionality, and extremely long service life. If you like to know more information about printed circuit boards, please visit the website http://www.rigiflex.com.