The strategic significance of rigid-flex printed circuit boards and their applications in critical fields of operation has increased their popularity in several industrial sectors. This blog will help the customers in taking a decision while selecting a reliable rigid-flex PCB manufacturer. However, before understanding the qualities of a reputed and efficient manufacturer, let us know a bit about rigid-flex PCBs and their importance and applications.

What is Rigid-flex PCB and what is its importance?

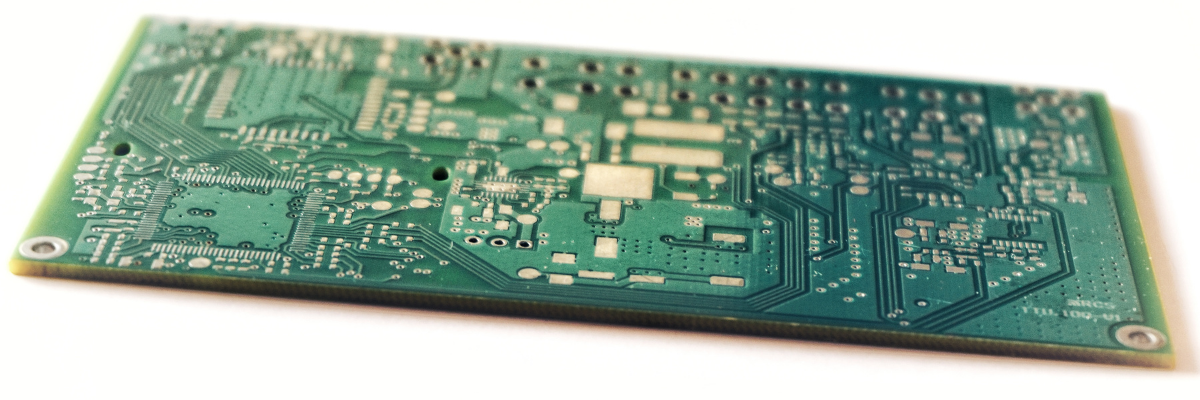

Rigid-flex is one of the three varieties of printed circuit boards, which combines both rigid and flexible PCBs. This type of PCBs is ideally used in critical applications where highly dense circuitry is required for saving a significant amount of space. This leads to the designing of light-weight electronic products.Rigid-flex PCB manufacturers have been fabricating this type of circuitry since 20 years for the military and aerospace industries.Here, the circuitry includes several flexible circuit inner layers carefully attached together with the help of an epoxy pre-preg bonding film. The unmatched versatility of rigid-flex PCBs has made its manufacturers design this type for simple as well as complex applications. Some of the industrial sectors using rigid-flex PCBs are automotive, medical, commercial, telecom, military, aerospace and so on.

How to know if the rigid-flex PCB manufacturer is one of the most reliable companies?

With so many service providers in the market, it becomes a challenging task to select a reliable and genuine PCB manufacturer. Considering the following aspects would help:

- Check and assess the depth of expertise and length of experience of the rigid-flex printed circuit board manufacturer. Check the kind of clients it serves across the globe.

- Check the varieties of products and services provided by the manufacturer, and the variety of materials and designing techniques used by it. Assess its technical acumen and knack for innovation.

- Check the varieties of industries served by the company as this reflects the in-depth competency of the company.

- Check the varied capabilities of the company in designing and manufacturing high-quality rigid-flex PCBs, and assess the benefits of the manufacturing process.

- Also, check out the PCB portfolios and customers’ reviews and testimonials to make some judgments.

Most importantly, ensure that the manufacturer provides a win-win situation for the customers by offering high-quality products withina short turnaround time and at cost effective prices.