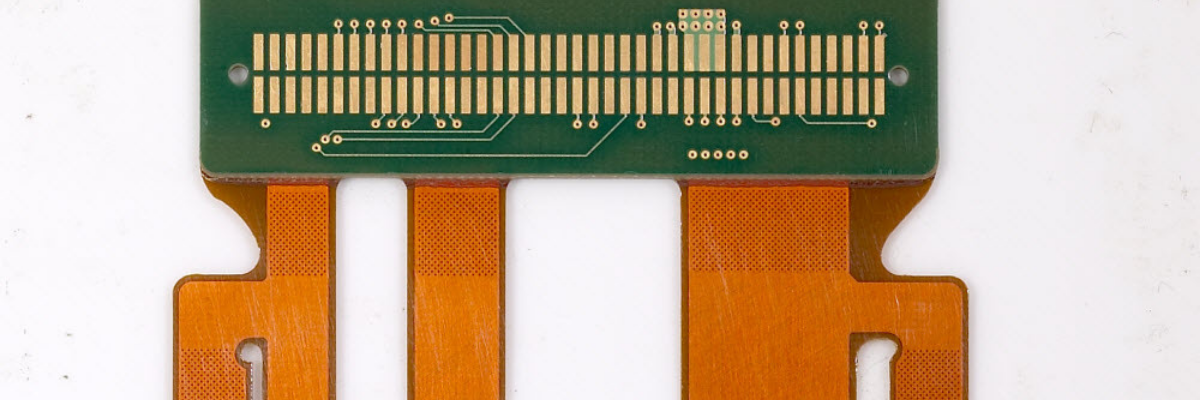

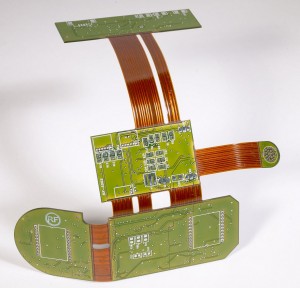

A six layer Rigid-Flex PCBs, as the name implies, is manufactured using six conductive copper layers. Designed specifically for use in industrial control, automobiles, power, lighting, and telecommunication, these PCBs allow for a high degree of design freedom.

Materials Used for Constructing 6 Layer Rigid-Flex:

Base Materials – The most commonly used base materials for manufacturing 6 layer Rigid-Flex is woven fiberglass impregnated with epoxy resin. The use of cured epoxy makes the board more rigid. Manufacturers also prefer Polyimide rather than normal epoxy resin to ensure extreme reliability in complicated applications. Polyimide is chosen due to their extreme flexibility, toughness, and heat resistance properties. Polyester (PET) is also another material of choice for the PCB fabrication. Manufacturers choose the best amongst these materials after analyzing the application requirements of customers.

Films – Manufacturers prefer PET films for producing 6 layers Rigid-Flex due to their corrosion and heat resistance properties. The thickness of PET films used for the PCB manufacturing vary from 1/3 mil to 3 mils.

Conductors – Copper is the most preferred conductor of choice for making 6 layer Rigid-Flex. Various types and forms of copper are used depending on the application requirements. Annealed copper is used when an application demands repeated creasing or movement of the flex circuit.

Adhesives – The use of high quality and appropriate adhesive is crucial to make a fine bonding between the conductor and films. Acrylic or epoxy based adhesives are the most commonly used adhesives to achieve a firm bonding. Silicones, hot-melt glues, and epoxy resins are also utilized for the purpose of bonding.

A better understanding of the properties and features of the aforementioned materials helps manufacturers in their mechanical design, evaluation and testing of the PCBs. For instance, a manufacturer who fabricates 6 layers Rigid-Flex pcb for the automobile industry must know the moisture, chemical, shock & vibration resistance properties of the materials used in the construction. This helps in enhancing the durability of PCBs when used in industry specific applications.