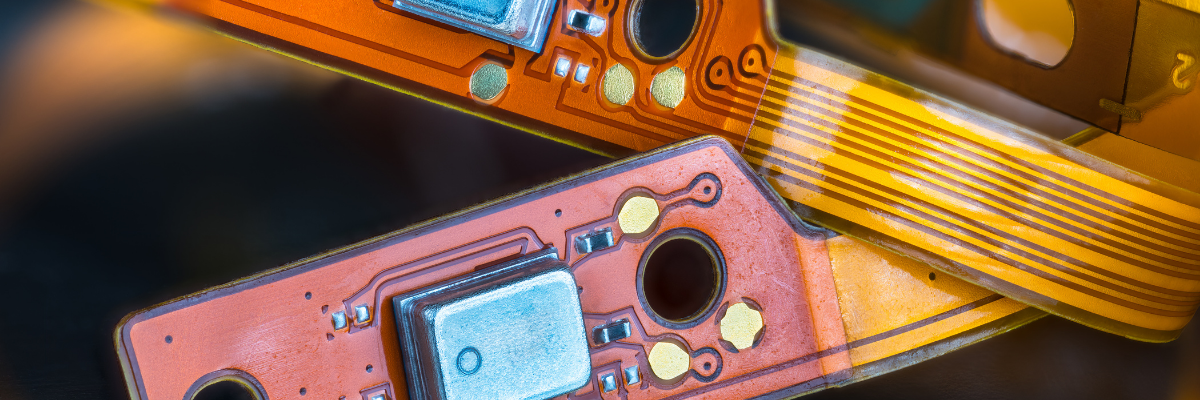

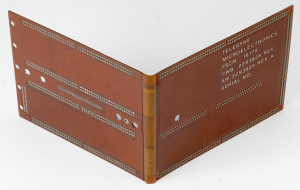

Bookbinding construction of Printed Circuit Boards (PCBs) is used to accommodate a higher count of boards. PCBs featuring bookbinding construction are used when the boards need to negotiate a tight bend. For example, a 12 Layer Flex with bookbinding will be able to meet tighter tolerances with regard to the bend radius when compared to a 12 layer PCB that is bonded. Thus, bookbound flex PCBs are extremely useful in applications, which require intentional or unintentional bending.

Advantages of Bookbinding Construction

PCBs with bookbinding construction are mostly used in critical applications. They feature the following advantages:

- One of the most efficient ways of creating a stacked PCB.

- Bookbinding of PCBs reduces stress experienced by the external circuits.

- They are compatible with all kinds of mounting and component fixing processes, such as SMT (Surface Mount Technology), through-hole technology (PTH), and wire bonding.

- The use of flexible material allows the PCB to perform bends of 180Ëš or more.

- It prevents the inner layers from buckling.

- It can be used for high density applications.

- It allows optimized (denser) circuitry as well.

- By reducing stress on the components and board, it increases the life of the PCB.

When fabricating PCBs with a high number of layers, the copper traces should be placed either at right angles to the bend or conically. This allows the circuitry to bend in the direction of the bend rather than against it. Hence, the stress experienced by the circuit is also much lower.

Although PCBs with bookbinding construction are expensive, they are extremely reliable. They are used in high-cost applications, which require superior performance. Flex bookbinding PCB provide dependable performance, and are used in critical operations that are not allowed to fail.