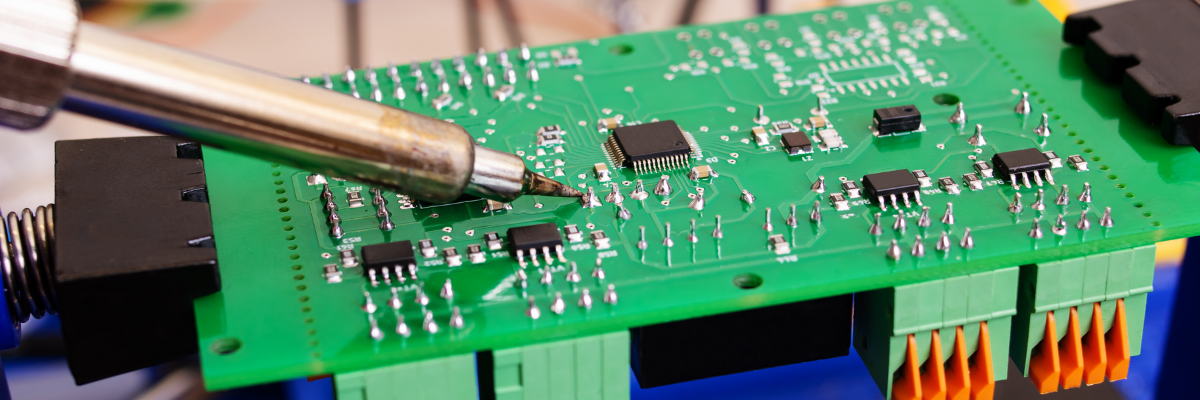

The constant usage of electronic products in our day-to-day life and the extensive array of devices we use for varied applications is quite evident of our dependence upon them. But have you ever thought what these devices are dependent upon for their smooth operation? Printed circuit boards to be precise. However, this blog will only focus on discussing the flexible circuit boards and what customers should expect from a flex PCB manufacturer.

What is a Flexible Printed circuit Board?

Flexible circuit boards are best suited for electronic devices, and are made of plastic layers like polyimide film (in many cases and for special purposes, fluorocarbon and aramid films are also used). The flexible laminate of the PCB consists of a conducting foil and dielectric substrates. The choice of raw materials used in flexible PCBs is based on the criticality of the applications and cost-efficiency of the finished products.

Services and quality of products expected from a reliable Flex PCB manufacturer

A flex PCB manufacturer ought to make sure of certain parameters to ensure high-quality product and satisfactory services to its customers. The first aspect that is considered while opting for a specific manufacturer is its number of years of experience and extent of expertise. The following factors signify the reliability of a specific flex PCB manufacturer:

- Considerable years of experience and proven track record in the domain of relevant manufacturing technology

- Justifiable and reasonable cost of service and other value added services like repair and calibration

- Provision of standard & custom flexible PCBs to customers that would suit their particular requirements

- Short turnaround time or convenient delivery within 1-5 days, along with free shipment services

- Excellent product quality, innovative technology and products meeting necessary certifications and military specifications

- Flex PCB manufacturers providing a wide gamut of specialized services in PCB prototype and PCB manufacturing are widely preferred

- A manufacturer should be adept in several high-tech fabrication processes in order to provide highly customized PCBs with unbeatable features and configurations

When it comes to choosing a flex PCB manufacturer, who offers more than the above-mentioned provisions, make sure to opt for Rigiflex as you can certainly rely on its experience, expertise and service excellence.