Two layer PCBs are the types of multilayer metal core PCBs, which are quite different from single layer PCBs due to their design. Many times, two layer PCBs are always confused with double sided more core PCBs. However, there is a vast difference between the two. This post discusses two layer PCBs, their capabilities, and applications in detail.

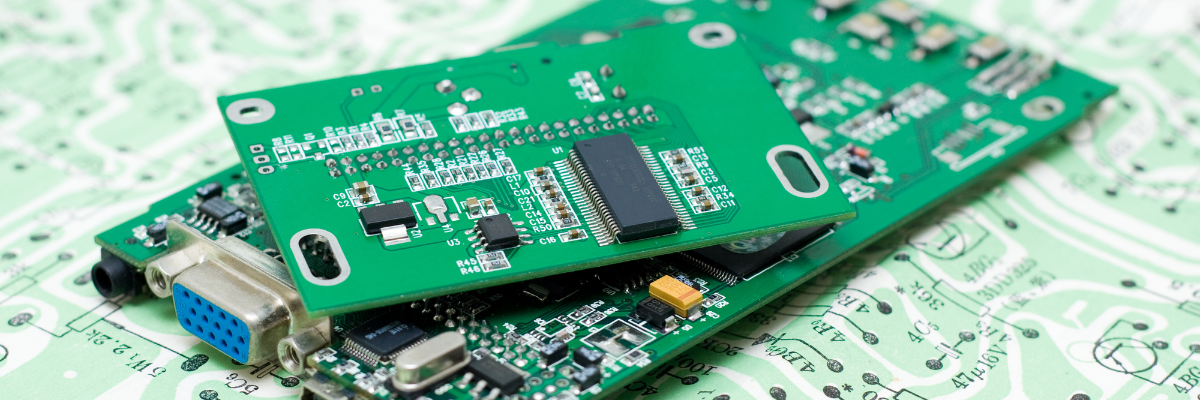

A Brief Introduction to Two (Double) Layer PCBs

As the name suggests, double (two) layer PCBs feature two layers of copper conductor on the same side of the metal core, which is usually aluminum, iron, or copper alloy. The metal base generally lies on the bottom side of the metal core PCB. The SMD can only be populated on the top.

Challenges in Two Layer PCB Assembly

Unlike single layer metal core PCB assembly, the double layer PCBs demand an additional step. The thermal conductor and a metal core is laminated together. This is a difficult task and demands experience and in-depth knowledge of technology. The assembly steps of these PCBs are very complex. The process of integrating metal base into the PCB requires hole plugging after the initial drilling. This is performed to isolate the metal base from the circuit.

3 Reasons Why Two Layer PCB’s Can be Your Choice

Following are the 3 advantages of two layer PCBs which make them popular over a single layer PCB.

- Improved Component Life: An extra layer of copper allows excellent heat dissipation than a single copper layer. This helps improve the component life. Also, the aluminum and copper alloys have better heat dissipation properties.

- High Component Density: The two layers of conductors allow PCB designers to add multiple tracks or increase connections for IC with high pin counts. Also, this high component density helps constrict the PCB size, thereby making it suitable for most modern day advanced electronic circuits. The double layer circuits are suited for complex circuits because they have large area for conductors than single sided PCBs.

- Capable of Handling Complex Situations: All the above mentioned factors combined with choice of excellent dielectric materials have helped improve stress handling capabilities of two layer circuit boards.

After reading the challenges in Two (Double) Layers MPCB, you might have understood, why there are only a few PCB assembly services offering these PCBs. Rigiflex is one of the reliable PCB assembly services providing standard and custom two (double layer) PCBs. The company supplies two layer PCBs for mission–critical applications. For more information on its manufacturing capabilities, and industrial applications.